AUTOMATIC DEBURRING MACHINE Designed for High Throughput and Accuracy

Driving Industrial Efficiency with Unmatched Precision

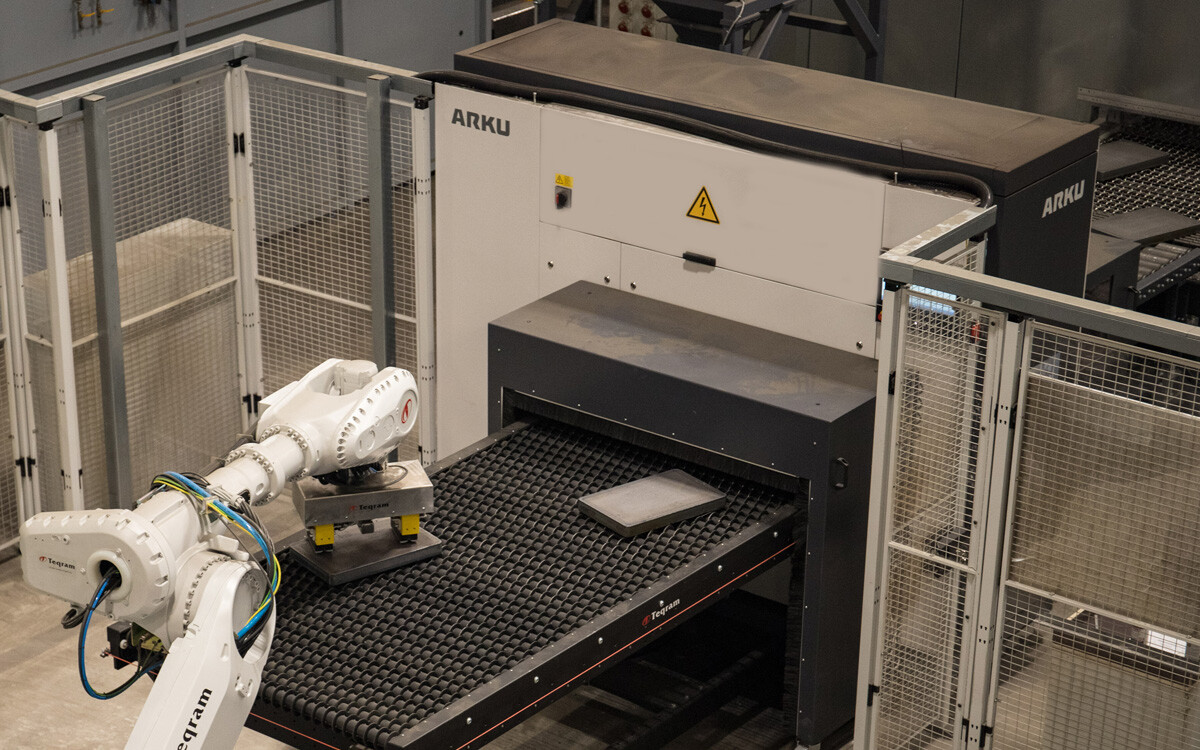

Manufacturing industries across the globe demand high-speed, accurate solutions for surface finishing, and the AUTOMATIC DEBURRING MACHINE stands as a leading innovation in this realm. Built to streamline production cycles and maintain uniform edge refinement, this machine delivers unmatched precision for high-volume operations. With advancements in automation and sensor technology, it is redefining how industries approach metal finishing without sacrificing speed or consistency.

Meeting High Production Needs Without Compromise

In fast-paced manufacturing setups, where volume and quality must go hand in hand, the AUTOMATIC DEBURRING MACHINE plays a crucial role. Designed to cater to continuous and demanding workflows, it processes a large number of components efficiently. Whether it’s sheet metal, forged parts, or machined components, the machine ensures smooth, burr-free surfaces across diverse shapes and materials. Its ability to maintain a consistent finish while operating at full speed makes it an indispensable asset in competitive production environments.

Advanced Features for Precision Edge Finishing

The core strength of a high-performance AUTOMATIC DEBURRING MACHINE lies in its ability to control every element of the finishing process with digital precision. From adjustable pressure controls to adaptive feed mechanisms, the machine tailors its operations to suit the exact geometry and material properties of each component. This ensures uniform deburring, eliminates sharp edges, and prevents variations that may otherwise affect product quality or assembly fit.

Automation That Minimizes Human Error

Manual deburring can lead to inconsistencies and potential safety hazards. The AUTOMATIC DEBURRING MACHINE eliminates such risks by employing programmable cycles and real-time feedback systems. These features ensure that each part receives the same treatment, regardless of batch size or complexity. The automation not only improves finish quality but also allows operators to focus on higher-value tasks, enhancing overall productivity.

Streamlined Integration Across Industrial Sectors

From automotive to aerospace and heavy machinery, the AUTOMATIC DEBURRING MACHINE adapts seamlessly to various manufacturing lines. Its modular design allows for easy customization and integration into existing production systems. This flexibility is critical for industries that require fast changeovers and minimal downtime, making the machine a perfect fit for both small-scale and large-scale operations alike.

Built for Consistent Quality Over Time

Longevity and durability are central to the design of any AUTOMATIC DEBURRING MACHINE. Engineered with robust materials, precision motors, and wear-resistant components, the machine delivers long-term performance even under continuous use. Its built-in diagnostics and low-maintenance design reduce unplanned downtime, ensuring that production targets are consistently met without compromising quality.

Energy Efficiency Meets Industrial Demand

As sustainability becomes more important across all industries, the modern AUTOMATIC DEBURRING MACHINE incorporates features that reduce energy usage and material waste. From efficient motor systems to precision abrasive control, these machines are designed to minimize environmental impact while still achieving optimal finishing results. This blend of eco-conscious engineering and industrial power creates value for both manufacturers and the planet.

Supporting High Standards of Safety and Compliance

Safety and regulatory compliance are paramount in today’s industrial settings. The AUTOMATIC DEBURRING MACHINE is equipped with protective enclosures, emergency stop systems, and safety sensors to ensure operator well-being. Moreover, its consistent and clean finish output helps manufacturers meet strict international standards, contributing to both product integrity and market competitiveness.

The Ultimate Tool for Scalable Production

For businesses looking to expand their output without sacrificing finish quality, the AUTOMATIC DEBURRING MACHINE offers a scalable solution. Its speed, accuracy, and automation capabilities allow manufacturers to handle growing demands without adding labor or sacrificing reliability. This adaptability positions the machine as a future-ready investment for any facility committed to excellence and operational growth.

Conclusion: Redefining the Future of Deburring

With precision at its core and productivity as its promise, the AUTOMATIC DEBURRING MACHINE is transforming how industries approach edge finishing. By combining speed, consistency, and advanced automation, it provides a solution that meets the challenges of modern manufacturing. As industries continue to evolve, machines like this one will remain essential in delivering the balance between quality and output that global markets demand.